Science-based approach to measuring emissions reductions supports Vale’s work to achieve 15% Scope 3 emissions reductions target

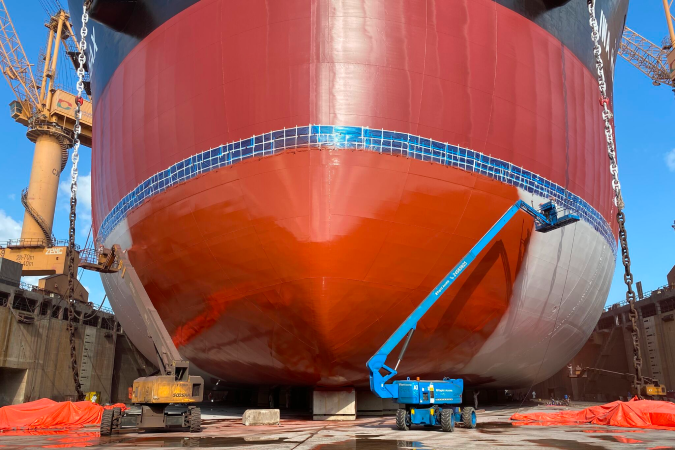

Mining company Vale reported significant efficiency gains and carbon emission reductions through its EcoShipping program, which includes the application of Hempel’s anti-fouling hull coating to its 400,314 dwt iron ore carrier, Liwa Max. Monitored through Hempel’s SHAPE performance system, the vessel achieved an estimated reduction of 6,700 tonnes in CO₂ emissions over an 18-month period. This result underscores Vale’s commitment to sustainability and operational efficiency, contributing to the decarbonisation of the maritime industry.

The vessel, which is owned and operated by Asyad Shipping and chartered by Vale, is one of several vessels being used in a pilot project within Vale’s EcoShipping program, an initiative aimed at reducing the environmental impact of the company’s maritime operations through in-service testing of a range of energy efficiency solutions onboard chartered-in vessels. The EcoShipping program seeks to enable Vale to deliver on its target of reducing Scope 3 emissions (from the wider value chain, of which shipping is a part) by 15% by 2035; . Focused on adopting and leveraging technologies and fleet modernization to reduce GHG emissions, the R&D program is based on a strong partnership with shipowners and solution providers to develop innovative energy-efficient projects, such as the rotor sails project and a pioneering project to incorporate multi-fuel tanks on iron ore carriers.

The specific coating system was chosen after three years of research by Instituto Technologico Vale (ITV - Vale Institute of Technology), which is a pioneering setup in feeding Vale with objective, technical insights for furthering decision making across all aspects of its business and operations.

Vale is committed to supporting the maritime industry in achieving the International Maritime Organization's (IMO) decarbonization targets. We want to work with industry partners that take our sustainability targets seriously, and we are pleased to see such positive outcomes from this project to test the impact of a high-performance hull coating. Knowing that the right anti-fouling solution can make such a marked improvement to the efficiency of any vessel is extremely encouraging.Rodrigo Bermelho, Global Head of Shipping, Vale

Hempel’s SHAPE Programme Validates Fuel and Emissions Savings for Vale Using Advanced Hull Coating and Digital Monitoring

This performance of the Hempaguard solution specifically was validated using Hempel’s SHAPE (Systems for Hull and Propeller Efficiency) programme, a methodology designed to monitor and measure the impact of hull coatings on vessel performance based both on ISO19030 and digital twin performance models. Through SHAPE, detailed performance data from Liwa Max was collected pre-and-post dry-dock and continuously analysed, confirming the substantial fuel savings and emissions reductions generated by the hull coating alone.

For this project, data is fed into Hempel’s SHAPE platform directly from Kongsberg Digital's Vessel Insight Connect. The platform is being used to enable Vale to collect consistent high frequency and quality data from all of the vessel’s within the EcoShipping Programme and compare the impact of energy efficiency technologies being tested, including rotor sails, and air lubrication technologies.

Vale’s commitment is highly commendable and reinforces how important the actions of the entire shipping industry are to enabling more sustainable supply chains. We are very pleased to have been able to demonstrate the significant strides that can be made by opting for a high-performance hull coating and taking an evidence-based approach to measuring its impact. We will continue to monitor and report on the coating’s performance until its next scheduled dry dock in 2028, as well as the additional fuel and emissions savings achieved.Mads Raun Bertelsen, Data & Technology Director, Hempel